·Paper Publications

Indexed by: Journal paper

Journal: Acta Biomaterialia

Included Journals: SCI

Discipline: Engineering

First-Level Discipline: Material Science and Engineering

Document Type: J

Volume: 153

Page Number: 614-629

Key Words: Additive manufacturing;Laser powder bed fusion;Corrosion fatigue;Zinc-magnesium;Triply periodic minimal surface

DOI number: 10.1016/j.actbio.2022.09.047

Date of Publication: 2022-09-23

Impact Factor: 10.633

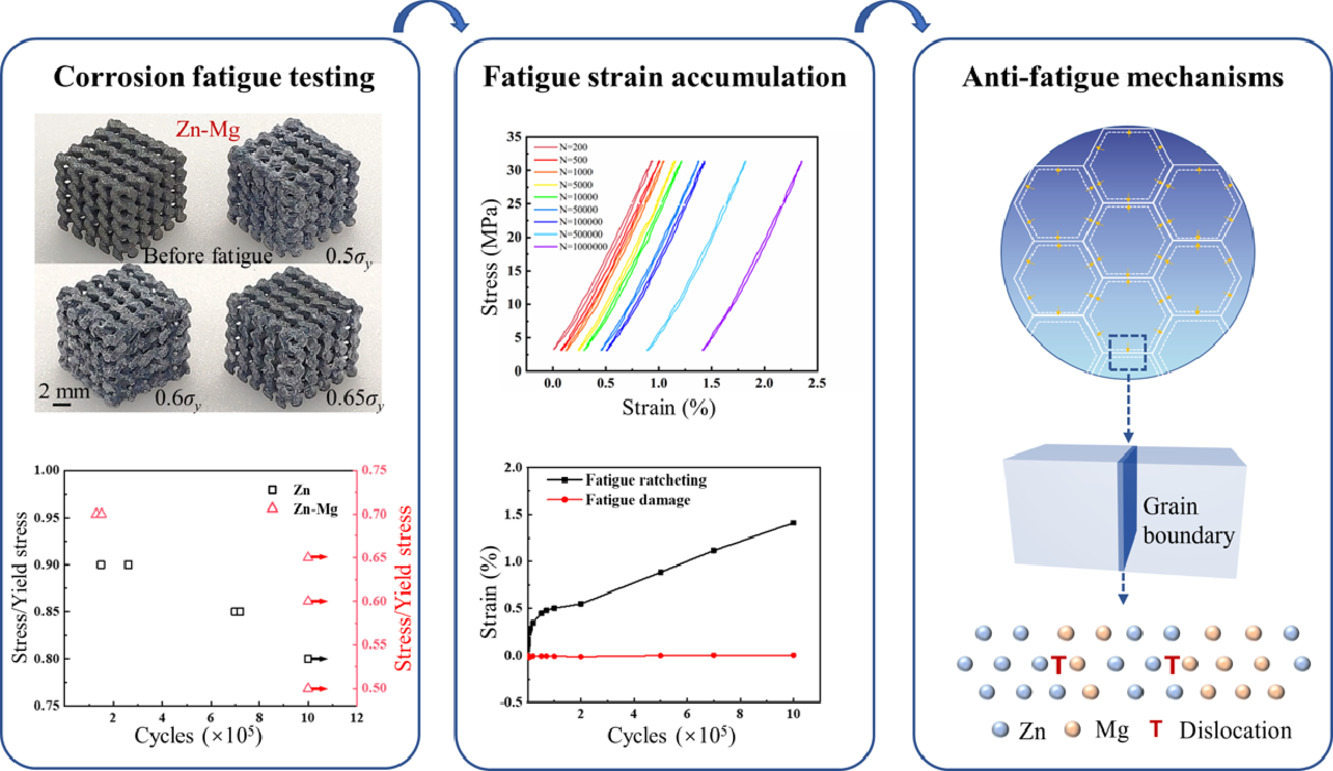

Abstract: Additively manufactured biodegradable zinc (Zn) alloy scaffolds constitute an important branch in orthopedic implants because of their moderate degradation behavior and bone-mimicking mechanical properties. This work investigated the corrosion fatigue response of a zinc-magnesium (Zn-Mg) alloy gyroid scaffold fabricated via laser-powder-bed-fusion additive manufacturing at the first time. The high-cycle compression-compression fatigue testing of the printed Zn-Mg scaffold was conducted in simulated body fluid, showing its favorable fatigue strength, structural reliability, and anti-fatigue capability. The printed Zn-Mg scaffold obtained a 227% higher fatigue strength than that of the printed Zn scaffold but 17% lower strain accumulation at 106 cycles. The accumulative strain of the Zn-Mg scaffold at its fatigue strength was dominant by fatigue ratcheting, since the fatigue damage strain of the scaffold was approximately zero. The corrosion products (ZnO and Zn(OH)2) were conducive to the inhibition of fatigue ratcheting and fatigue damage. Dislocation pile-up and solid solution phases at the grain boundaries of the Zn-Mg scaffold could retard the spreading of the crack tip and impede excessive grain coarsening, improving its fatigue endurance limit. Notably, the printed Zn-Mg scaffold could dissipate the fatigue energy through moderate grain boundary migration, thus reducing its plastic deformation. These findings illuminated the anti-fatigue mechanisms related to microstructural features and corrosive environments and highlighted the promising prospects of additively manufactured Zn-Mg scaffolds in orthopedic applications.

Links to published journals: https://doi.org/10.1016/j.actbio.2022.09.047