·Paper Publications

Indexed by: Journal paper

Journal: Materials Science and Engineering: A

Included Journals: SCI

Document Type: J

Key Words: Laser powder bed fusion;Shape memory alloy;Shape memory effect;Martensite

Date of Publication: 2023-08-05

Impact Factor: 6.4

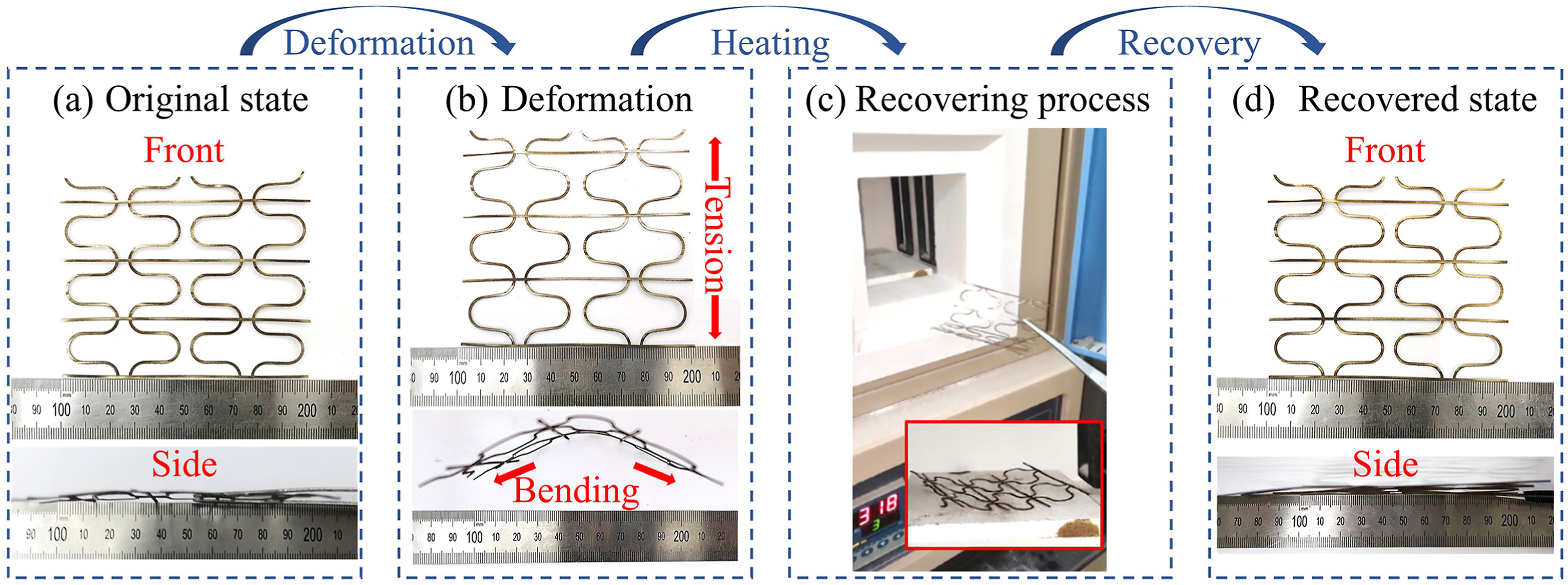

Abstract: A copper-based shape memory alloy Cu-11.85Al-3.2Mn-0.1Ti with desirable superelasticity and shape memory effect was printed by laser powder bed fusion (LPBF), which demonstrated the feasibility of engineering applications through the deformation and recovery of complex corrugated structural components. The microstructure of LPBF-printed Cu-11.85Al-3.2Mn-0.1Ti was composed of full β1' martensite with a high density of stacking faults and twin crystals. The abnormal phase constitution of full martensite in the printed Cu-11.85Al-3.2Mn-0.1Ti is correlated to substrate preheating and thermal cycling during LPBF. The start and finish transformation temperatures of martensite (Ms and Mf) and austenite (As and Af) were 172.5 °C, 144.4 °C, 180.2 °C and 209.2 °C, respectively. The printed samples exhibited compressive strength of 1319 MPa with a compressive fracture strain of 16.1%. The printed alloy displayed remarkable superelasticity and shape memory effect. The superelastic recovery rate reached a maximum value of 87% at 6% pre-strain, corresponding to a superelastic recovery strain of 5.22%. The mechanism of superelasticity is attributed to the rubber-like deformation behavior. Moreover, the pre-strained samples demonstrated a desirable shape memory effect under the temperature stimulation, where the shape memory recovery rate of up to 100% at a pre-strain of 6%, corresponding to a shape memory recovery strain of 0.78%. The reasons for the favorable shape memory effect were: (i) the thermoelastic inversion of martensitic transformation and (ii) the precipitation of γ2(Cu9Al4) phase along the grain boundaries. As a result, these findings suggest that the LPBF technique can produce Cu-Al-Mn-Ti parts with superelasticity and good shape memory properties, which provided valuable references for printed copper-based shape memory alloys with full martensitic structures.

Links to published journals: https://doi.org/10.1016/j.msea.2023.145475