个人信息

Personal information

教授 博士生导师 硕士生导师

性别:男

在职信息:在职

所在单位:材料科学与工程学院

学历:研究生(博士)毕业

学位:工学博士学位

毕业院校:华中科技大学

学科:材料加工工程曾获荣誉:

2017 华中科技大学学术前沿青年团队负责人

2017 黄鹤英才“专项”计划

2016 江苏省双创人才

2016 华中科技大学师德三育人奖

论文类型:期刊论文

发表刊物:Journal of Materials Science & Technology

收录刊物:SCI

发表时间:2023-05-22

影响因子:10.319

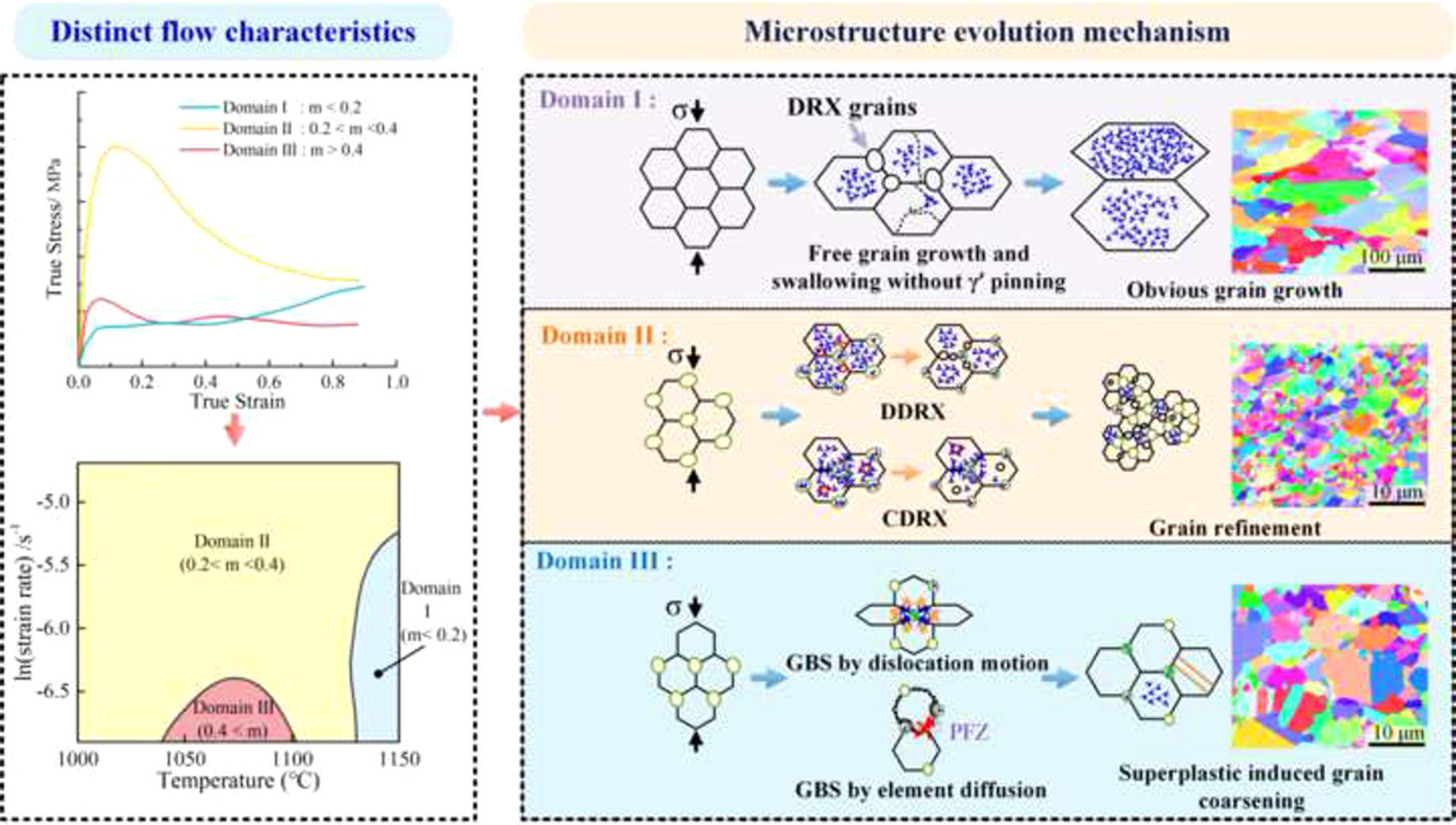

摘要:Isothermal forging (IF) is an effective method for forming difficult-to-deform materials like P/M superalloys. Understanding the isothermal compression microstructural evolution mechanism of a novel P/M superalloy provides the basis for its optimized IF planning. In this study, the isothermal compression tests of a novel fine-grained P/M nickel-based superalloy were carried out at 1000–1150 °C with strain rates of 0.001–0.01 s−1. The results indicated that the alloy exhibits three distinct flow characteristics: continuous softening after reaching the peak stress, near-steady superplastic flow, and discontinuous hardening, corresponding to different strain rate sensitivity exponent (m) values. Varied microstructural evolution mechanisms, including grain boundary sliding (GBS), dynamic recrystallization (DRX), and grain growth, are dominated in different m-value domains. Meanwhile, different roles of primary γ' play in microstructural evolution were clarified. A moderate fraction of primary γ' with 8.5%–14.2% can well coordinate the GBS and hinder excessive grain growth at a high m value domain (m > 0.4). When 0.2 < m < 0.4, the role of the primary γ' is changed to promote dislocation accumulation, accelerating the nucleation of DRXed grains. As the primary γ' is dissolved at 1150 °C, obvious grain growth was observed after compression. Work hardening effect by overgrown grains competed with DRX softening results in the discontinuous rising stress.

发布期刊链接:https://doi.org/10.1016/j.jmst.2023.03.042