个人信息

Personal information

教授 博士生导师 硕士生导师

性别:男

在职信息:在职

所在单位:材料科学与工程学院

学历:研究生(博士)毕业

学位:工学博士学位

毕业院校:华中科技大学

学科:材料加工工程曾获荣誉:

2017 华中科技大学学术前沿青年团队负责人

2017 黄鹤英才“专项”计划

2016 江苏省双创人才

2016 华中科技大学师德三育人奖

论文类型:期刊论文

发表刊物:Ceramics International

收录刊物:SCI

学科门类:工学

文献类型:J

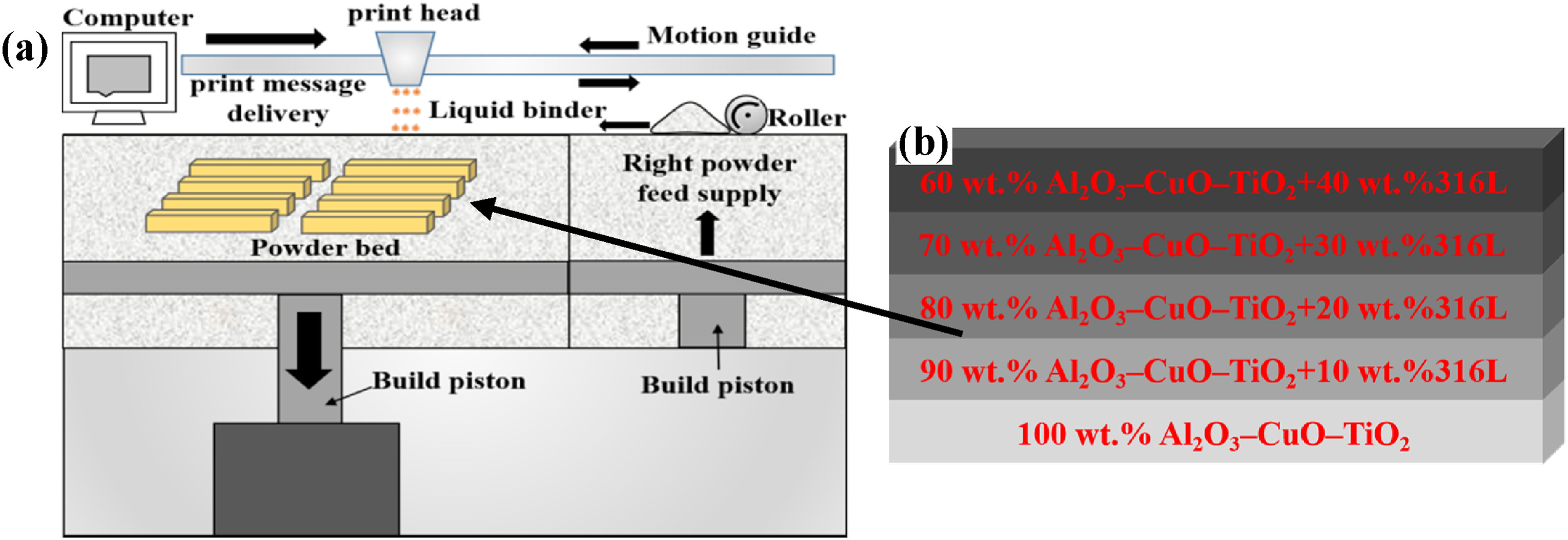

关键字:Binder jetting additive manufacturing;Al2O3–CuO–TiO2/316L FGMs;Relative density;Microstructure;Crack deflection;Toughening mechanism

发表时间:2023-07-06

影响因子:5.2

摘要:Al2O3-based ceramic functionally graded materials (FGMs) containing 1 wt.% CuO and 4 wt.% TiO2 as sintering aids and 0–40 wt.% 316L as a toughening phase are fabricated by binder jetting additive manufacturing, and the low-temperature co-sintering toughening mechanism was studied. According to the 3D Stereo Microscope and XRD results, the interfacial microstructure exhibited a noticeable gradient change after being sintered from 1200 °C to 1450 °C for 2 h, and the main phases were Al2O3, γ-austenitie, Fe3C and a small amount of δ-ferrite. The FGMs sintered at 1450 °C had maximum relative density, X–Z-axis dimensional shrinkage and average bending strength values of 70.05%, 4.89%, 10.15%, 17.53% and 26.9 ± 0.87 MPa, respectively. Bending cracks originated from the pure Al2O3-based ceramic layer and gradually propagated to the high-316L side, accompanied by the crack bridging and deflection phenomena. The maximum crack deflection degree was about 90° at 1200 °C and 1400 °C. Obviously, the existence of crack bridging and deflection illustrated that 316L addition effectively improves the toughness of FGMs.

发布期刊链接:https://doi.org/10.1016/j.ceramint.2023.06.039