个人信息

Personal information

教授 博士生导师 硕士生导师

性别:男

在职信息:在职

所在单位:材料科学与工程学院

学历:研究生(博士)毕业

学位:工学博士学位

毕业院校:华中科技大学

学科:材料加工工程曾获荣誉:

2017 华中科技大学学术前沿青年团队负责人

2017 黄鹤英才“专项”计划

2016 江苏省双创人才

2016 华中科技大学师德三育人奖

论文类型:期刊论文

发表刊物:Materials Science and Engineering: A

收录刊物:SCI

文献类型:J

关键字:Laser powder bed fusion;Shape memory alloy;Shape memory effect;Martensite

发表时间:2023-08-05

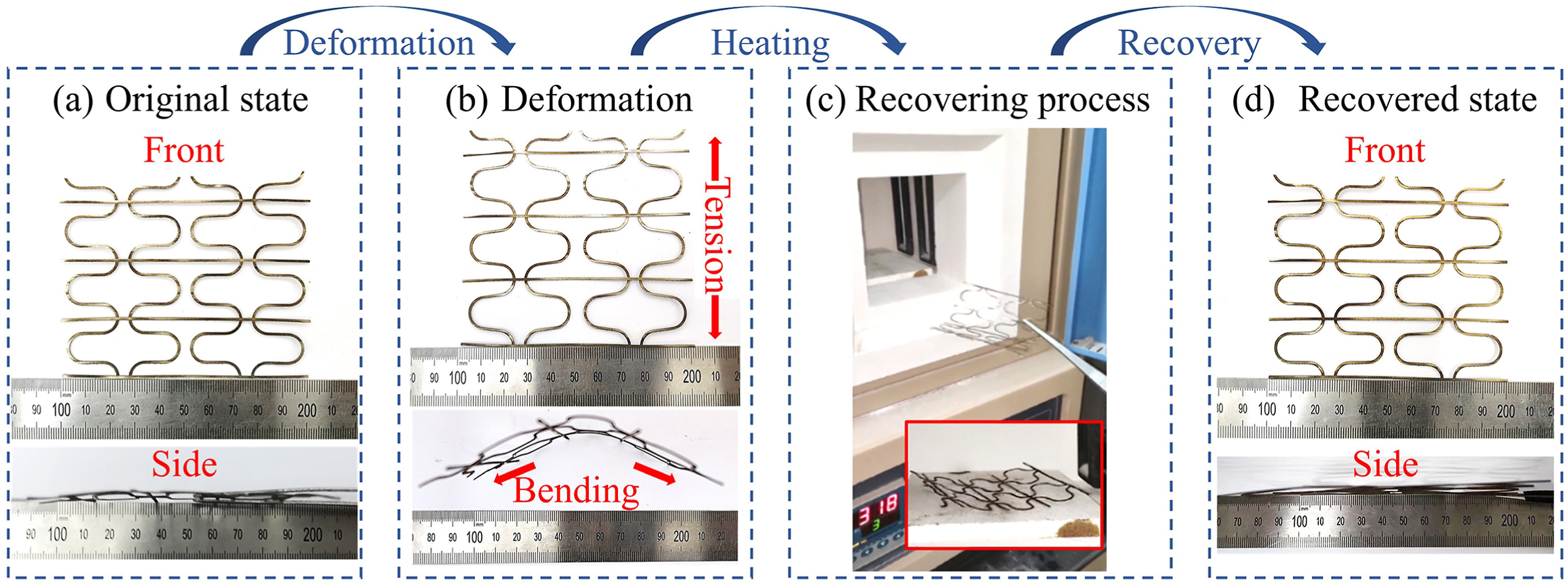

影响因子:6.4

摘要:A copper-based shape memory alloy Cu-11.85Al-3.2Mn-0.1Ti with desirable superelasticity and shape memory effect was printed by laser powder bed fusion (LPBF), which demonstrated the feasibility of engineering applications through the deformation and recovery of complex corrugated structural components. The microstructure of LPBF-printed Cu-11.85Al-3.2Mn-0.1Ti was composed of full β1' martensite with a high density of stacking faults and twin crystals. The abnormal phase constitution of full martensite in the printed Cu-11.85Al-3.2Mn-0.1Ti is correlated to substrate preheating and thermal cycling during LPBF. The start and finish transformation temperatures of martensite (Ms and Mf) and austenite (As and Af) were 172.5 °C, 144.4 °C, 180.2 °C and 209.2 °C, respectively. The printed samples exhibited compressive strength of 1319 MPa with a compressive fracture strain of 16.1%. The printed alloy displayed remarkable superelasticity and shape memory effect. The superelastic recovery rate reached a maximum value of 87% at 6% pre-strain, corresponding to a superelastic recovery strain of 5.22%. The mechanism of superelasticity is attributed to the rubber-like deformation behavior. Moreover, the pre-strained samples demonstrated a desirable shape memory effect under the temperature stimulation, where the shape memory recovery rate of up to 100% at a pre-strain of 6%, corresponding to a shape memory recovery strain of 0.78%. The reasons for the favorable shape memory effect were: (i) the thermoelastic inversion of martensitic transformation and (ii) the precipitation of γ2(Cu9Al4) phase along the grain boundaries. As a result, these findings suggest that the LPBF technique can produce Cu-Al-Mn-Ti parts with superelasticity and good shape memory properties, which provided valuable references for printed copper-based shape memory alloys with full martensitic structures.

发布期刊链接:https://doi.org/10.1016/j.msea.2023.145475