个人信息

Personal information

教授 博士生导师 硕士生导师

性别:男

在职信息:在职

所在单位:材料科学与工程学院

学历:研究生(博士)毕业

学位:工学博士学位

毕业院校:华中科技大学

学科:材料加工工程曾获荣誉:

2017 华中科技大学学术前沿青年团队负责人

2017 黄鹤英才“专项”计划

2016 江苏省双创人才

2016 华中科技大学师德三育人奖

论文类型:期刊论文

发表刊物:Additive Manufacturing

收录刊物:SCI

学科门类:工学

一级学科:机械工程

文献类型:J

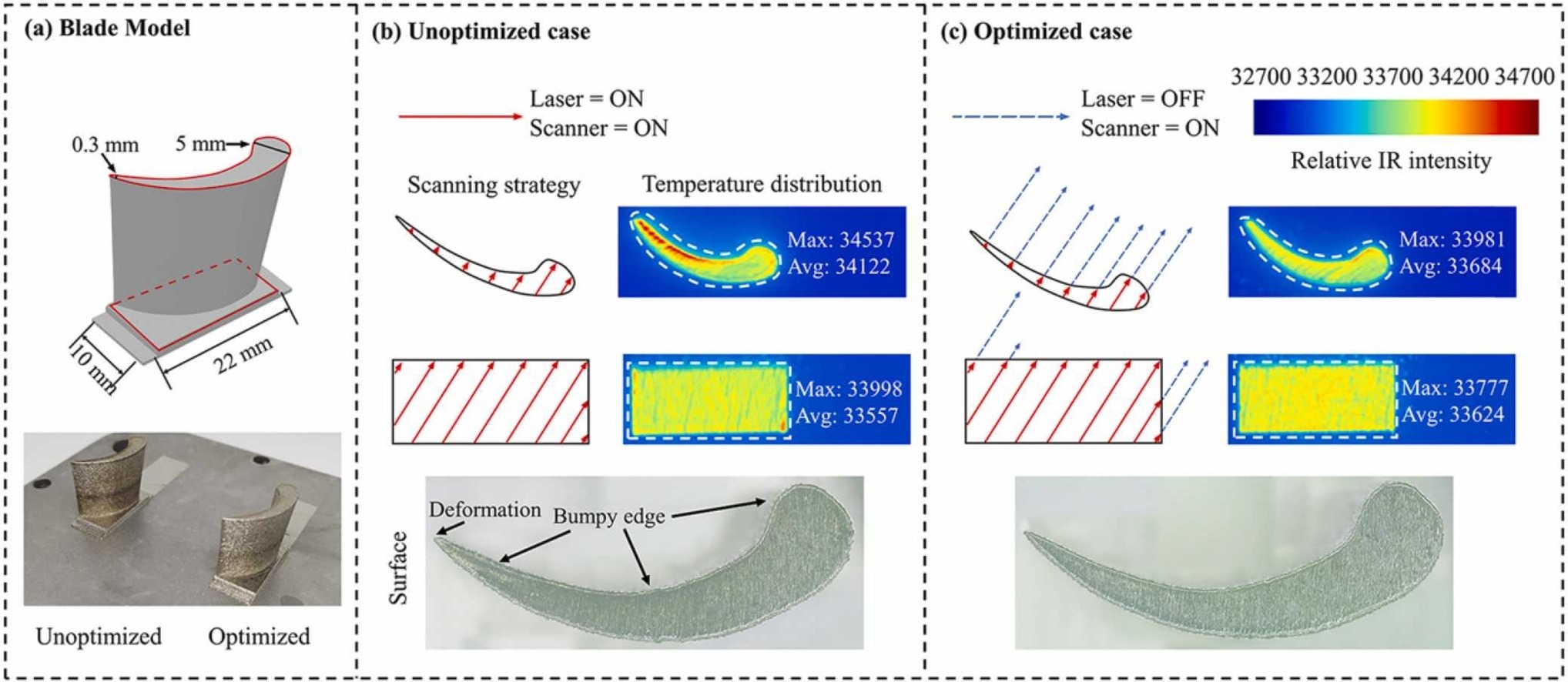

关键字:Laser powder bed fusion;Additive manufacturing;Heat accumulation;Short scanning lines;Optimized scanning strategy

DOI码:10.1016/j.addma.2022.103256

发表时间:2022-10-27

影响因子:11.632

摘要:During laser powder bed fusion (LPBF) additive manufacturing of components with complex geometries, short scanning lines easily induce localized excessive heat accumulation, resulting in poor manufacturing qualities, e.g., rough surface and low hardness, etc. An optimized scanning strategy was proposed to mitigate this heat accumulation to be consistent with the standard case. In the proposed strategy, a specific length of scanning line without laser energy was added to each short scanning line, making each scanning line of the same length. The temperature simulation results of 1 mm thin-walled specimen indicated that the conventional scanning strategy could easily drive a harsh increase in peak temperature, further leading to a harsh increase in melt pool size. After applying the optimized scanning strategy, the peak temperature and melt pool size of the 1 mm thin-walled specimen were almost similar to those of the standard specimen. Meanwhile, the corresponding experiments indicated that the average surface roughness and hardness of 1 mm thin-walled case processed by conventional scanning was Ra70 and 320 HV10. The deformation and bumpy area could be observed on the surface, the porosity was high, and the grain size tended to be larger. After optimization, the average surface roughness was decreased to Ra37 and the hardness was increased to 370 HV10. In addition, the above metallurgical defects were greatly reduced. The above scanning strategy was integrated into the self-developed LPBF equipment and manufacturing process, and the thin-walled blade model was processed to verify the feasibility of the optimized scanning strategy for complex parts. Since the scanning strategy is independent of material and process parameters, it is beneficial to improve the process and quality stability of LPBF manufacturing complex parts.

发布期刊链接:https://doi.org/10.1016/j.addma.2022.103256