个人信息

Personal information

教授 博士生导师 硕士生导师

性别:男

在职信息:在职

所在单位:材料科学与工程学院

学历:研究生(博士)毕业

学位:工学博士学位

毕业院校:华中科技大学

学科:材料加工工程曾获荣誉:

2017 华中科技大学学术前沿青年团队负责人

2017 黄鹤英才“专项”计划

2016 江苏省双创人才

2016 华中科技大学师德三育人奖

论文类型:期刊论文

发表刊物:Journal of Materials Research and Technology

收录刊物:SCI

学科门类:工学

文献类型:J

卷号:22

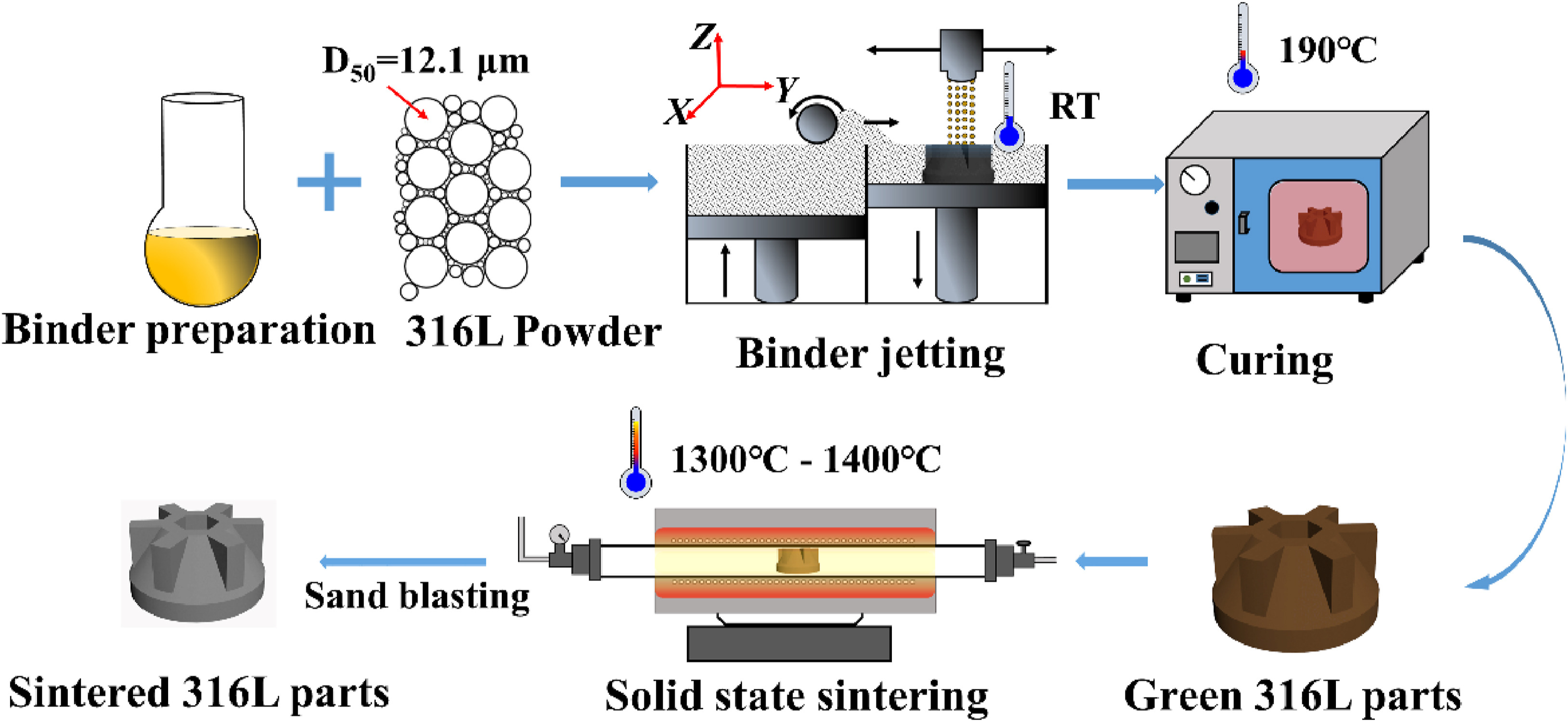

关键字:Binder jetting;316L;Sintering temperature;Pores formation;Microstructure evolution;Strength

发表时间:2022-12-19

影响因子:6.267

摘要:Binder jetting (BJ) selectivity jets binders on powders to form green parts efficiently. The following sintering process is indispensable to consolidating as-printed loose parts, inevitably introducing shrinkage and grain growth. The pore morphology and grain size will change significantly in the sintering process, directly affecting the sintered parts' density and mechanical properties. However, there is no research on the microstructure evolution of BJ 316L in the sintering process to date, which is essential for the further application of BJ 316L. This study used a solid state sintering process to consolidate the BJ 316L green parts. The effect of vacuum sintering temperature (1300 °C–1400 °C) on the density, porosity, linear shrinkage, microstructure evolution, and tensile properties of the as-sintered parts was investigated. Results indicated that the sintering temperature significantly affects the properties of the sintered 316L parts. Notably, the grain size and tensile strength strongly correlate with porosity. The sintered 316L parts have a relative density of 92.0% and preferable mechanical properties (ultimate tensile strength of up to 473.7 MPa and elongation of up to 40.22%) after sintering at 1380 °C. The pores in the sintered BJ 316L were distinguished into three types according to pores' size and distribution characteristics. The potential influences of these three types of pores on the properties of the sintered BJ 316L were discussed. This work is engaged in providing a detailed reference for the densification and microstructure evolution of BJ 316L parts.

发布期刊链接:https://doi.org/10.1016/j.jmrt.2022.12.096